Introduction

The cycle length in a regenerative thermal oxidizer represents a critical operational parameter that influences efficiency, energy recovery, and pollutant destruction in industrial air pollution control systems. An RTO regenerative thermal oxidizer employs a periodic switching mechanism to regenerate ceramic beds, enabling high thermal efficiency while treating volatile organic compounds (VOCs) and hazardous air pollutants (HAPs). Understanding cycle duration ensures optimal performance, compliance with environmental regulations, and minimized operational costs. This article explores the factors determining cycle length, typical durations, and best practices for system design.

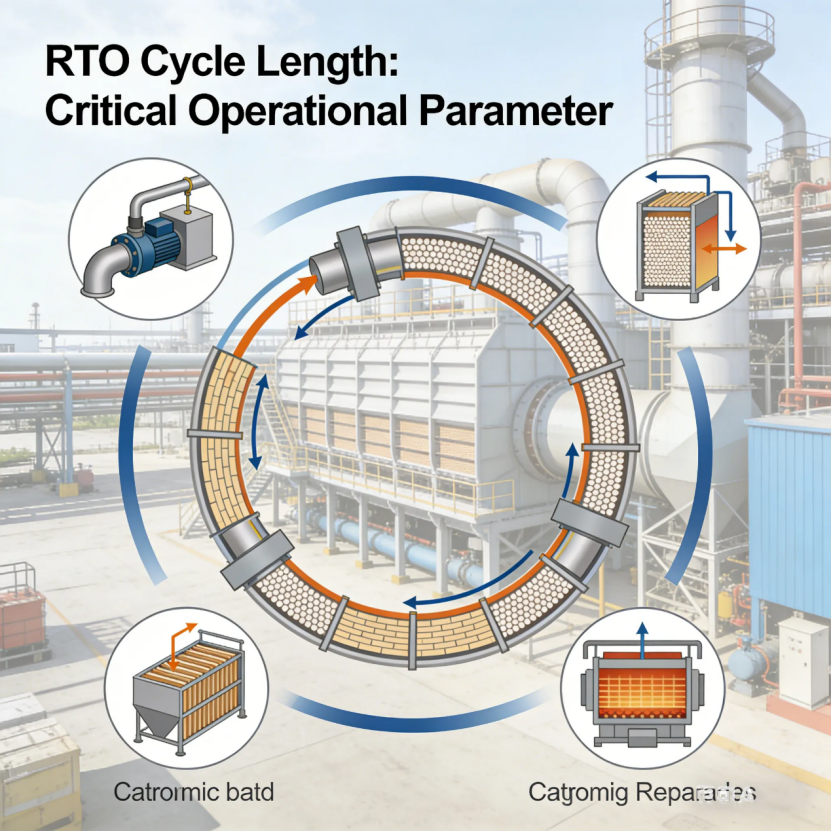

Understanding RTO Basics

A fundamental grasp of RTO operations clarifies the role of the cycle. An RTO system consists of multiple ceramic media beds that alternate between absorbing heat from outgoing clean exhaust and preheating incoming polluted air. The process begins with contaminated air entering one bed, where it gains heat before reaching the combustion chamber for oxidation at elevated temperatures, typically 1,400°F to 1,600°F (760°C to 870°C). The resulting clean, hot gases then pass through another bed, transferring heat to the media. Valves switch the flow direction periodically, defining the cycle and facilitating regenerative heat recovery up to 95% efficiency.

RTOs excel in applications with moderate to high airflow and low VOC concentrations, such as in chemical, printing, and coating industries. Unlike direct-fired or catalytic oxidizers, the regenerative design reduces fuel needs by reusing captured heat, but cycle timing must balance heat transfer effectiveness with system stability to avoid pressure fluctuations or incomplete pollutant removal.

Key Factors Affecting Cycle Length

Several variables influence the duration of an RTO thermal oxidizer cycle, requiring careful consideration during design and operation.

Process Stream Characteristics

The composition and flow rate of the exhaust stream play a pivotal role. High VOC concentrations generate more heat during oxidation, potentially allowing shorter cycles to maintain bed temperatures. Conversely, low-concentration streams may necessitate longer cycles to accumulate sufficient heat for efficient recovery. Flow rates also matter; higher volumes demand quicker cycles to prevent bed overheating or underutilization, while variable flows require adjustable timing for consistent performance.

Bed Design and Media Properties

The number and configuration of ceramic beds affect cycle length. Two-bed systems often feature cycles of 1 to 3 minutes, while three-bed or multi-bed configurations can extend to 4 minutes or more for enhanced purging and reduced emissions during switches. Media type—such as saddles, honeycomb blocks, or structured packing—influences heat transfer rates; denser media may support shorter cycles due to faster energy exchange, but they increase pressure drop, necessitating a balance.

Operating Temperature and Efficiency Goals

Cycle duration correlates with combustion temperature and desired thermal energy recovery (TER). Higher temperatures accelerate oxidation but may shorten cycles to manage heat buildup. Efficiency targets, often aiming for 95% or higher TER, guide timing; longer cycles allow more thorough heat absorption, reducing supplemental fuel use, whereas shorter ones enhance responsiveness to process changes.

Regulatory and Safety Considerations

Environmental standards, such as those from the EPA, mandate minimum destruction removal efficiencies (DRE), typically 98% or greater, which indirectly impact cycle length by requiring adequate residence time in the chamber—usually 0.5 to 1 second, distinct from the overall cycle. Safety protocols, including valve switching frequency, prevent excessive wear or thermal stress, often limiting cycles to avoid rapid cycling that could lead to mechanical failures.

Typical Cycle Durations

Cycle lengths in regenerative thermal oxidizers vary by application but generally fall within specific ranges based on industry data. Standard two-bed RTOs commonly operate with cycles of 60 to 180 seconds (1 to 3 minutes), optimizing heat recovery without excessive valve actuation. For larger or more complex systems, such as those handling halogenated compounds, cycles extend to 240 seconds (4 minutes) to ensure complete purging and minimize cross-contamination.

In practice, a printing facility might employ 2-minute cycles for steady VOC loads, while a chemical plant could use 3-4 minute intervals for variable streams. These durations are adjustable via programmable logic controllers (PLCs), allowing operators to fine-tune based on real-time monitoring of temperature, pressure, and emissions.

Optimization and Maintenance Strategies

To achieve ideal cycle lengths, engineers conduct thorough process audits, including flow and composition analysis, during the design phase. Advanced modeling software simulates scenarios to predict optimal timing, preventing undersized cycles that cause incomplete destruction or oversized ones that waste energy.

Maintenance is essential for consistent cycle performance. Regular inspections of valves, seals, and media prevent leaks or blockages that could force adjustments. Implementing predictive analytics, such as monitoring bed temperature differentials, enables proactive cycle modifications, extending equipment life and reducing downtime.

Considerations for Cost and Implementation

When evaluating implementation, regenerative thermal oxidizer cost encompasses not only initial capital for beds and controls but also operational expenses tied to cycle efficiency. Shorter cycles may increase valve wear, elevating maintenance costs, while longer ones enhance energy savings. Modular designs facilitate scalability, allowing cycle adjustments for future expansions without full system overhauls. Lifecycle assessments often reveal that optimized cycles yield payback periods of 2-5 years through reduced fuel consumption.

Best Practices and Case Studies

Adhering to best practices ensures effective cycle management. Reference standards like NFPA 86 for safe operations and integrate redundancies, such as backup valves, for reliability. Collaborate with experts to customize cycles based on site-specific data.

Case studies illustrate success: A coating operation with 20,000 SCFM flow implemented 2.5-minute cycles, achieving 98% DRE and 96% TER, saving $120,000 annually in fuel. In pharmaceuticals, 4-minute cycles for halogenated VOCs incorporated scrubbers, ensuring compliance and minimizing byproducts.

Conclusion

The cycle length in a regenerative thermal oxidizer is a dynamic parameter, typically ranging from 1 to 4 minutes, shaped by process needs, design features, and efficiency objectives. By addressing these elements systematically, industries can enhance pollutant control, energy conservation, and regulatory adherence. For tailored applications, professional consultation refines cycle strategies to maximize system value and sustainability.