When it comes to manufacturing durable and precise plastic parts, choosing the right injection molding company is one of the most important business decisions you can make. Whether you need small prototype runs or full-scale production, finding reliable injection molding companies near me ensures high-quality components, cost efficiency, and consistent performance.

With so many options available, how do you select the right partner for your project? The answer lies in understanding what makes a plastic injection molding company stand out — from technical expertise and equipment quality to customer service and production capacity.

At Rapid Molding, we specialize in helping clients across industries bring their ideas to life through precision plastic injection molding. Here’s what to look for when choosing the best molding company near you.

1. Technical Expertise and Industry Experience

When searching for injection molding companies near me, the first thing to evaluate is their level of technical expertise. Plastic injection molding is a complex process that requires deep knowledge of materials, tooling, and design engineering.

An experienced manufacturer will have skilled plastic injection molders who understand how different thermoplastics behave under pressure and temperature. They’ll also know how to design molds that produce consistent, high-quality parts — even in high-volume production runs.

Choose a company that has worked with diverse industries such as automotive, medical, consumer electronics, or industrial components. Experience in your specific sector ensures that the team understands your quality requirements and regulatory standards.

2. In-House Mold Design and Manufacturing

A key indicator of a professional molding company is its ability to design and build its own molds. The plastic injection molding process depends heavily on the quality of the mold itself. If the mold is poorly designed, even the most advanced machinery won’t produce accurate parts.

When comparing injection molding companies near me, look for one that offers in-house mold making or collaborates closely with trusted mold fabricators. In-house tooling gives the company better control over quality, design adjustments, and turnaround times.

Rapid Molding, for example, has dedicated tooling experts who create high-precision molds for every project. This capability allows for faster prototype development, improved accuracy, and easier maintenance throughout the mold’s lifespan.

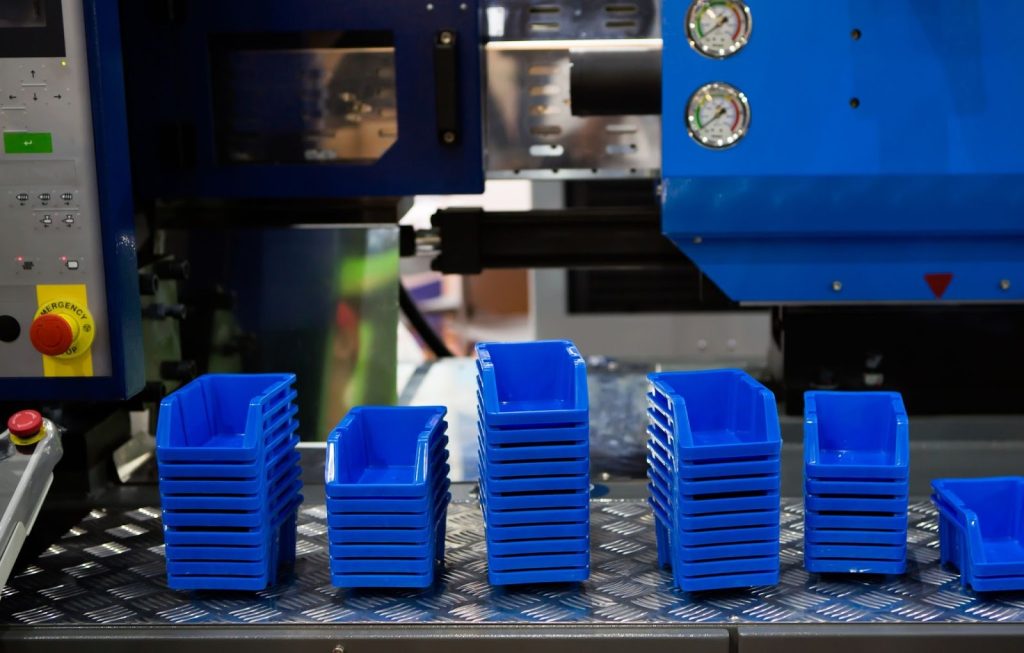

3. Advanced Equipment and Technology

Modern plastic injection molding requires state-of-the-art equipment to ensure precision and efficiency. Ask potential suppliers about their machinery and capabilities.

The best plastic injection molders use automated molding machines with tight control over temperature, pressure, and cycle time. Robotic handling systems, advanced cooling technology, and automated inspection tools also enhance productivity and consistency.

Companies that invest in the latest equipment demonstrate a commitment to quality and innovation. They can handle both small and large-scale production while maintaining strict quality standards.

4. Quality Control and Certifications

Quality is non-negotiable in plastic injection molding. Whether you’re manufacturing safety-critical components or consumer goods, each part must meet exact tolerances and specifications.

When evaluating injection molding companies near me, always check their quality assurance systems. Do they have ISO certifications? What inspection methods do they use? How do they verify material traceability?

Reliable plastic injection molders implement strict quality control at every stage — from raw material inspection to final part validation. Look for companies that use real-time process monitoring and dimensional inspections to ensure every product meets your expectations.

5. Material Selection and Guidance

Different projects require different materials. A reputable plastic injection molding partner should offer expertise in material selection, helping you choose the right resin for your part’s function and environment.

For instance, ABS is known for toughness and rigidity, nylon for flexibility and wear resistance, and polycarbonate for transparency and impact strength. Professional plastic injection molders understand how to balance performance, aesthetics, and cost-effectiveness based on your product requirements.

By working with experts who guide you through resin selection, you can avoid common issues like warping, cracking, or underperformance.

6. Prototyping and Product Development Support

Before going into full production, prototyping allows you to validate design, function, and fit. Not all injection molding companies near me provide rapid prototyping services — but it’s a crucial part of reducing risks and costs later.

Companies like Rapid Molding use 3D printing and low-volume plastic injection molding to create sample parts quickly. This helps you test performance, identify design improvements, and shorten the overall time to market.

A company that supports you from prototype to production demonstrates flexibility and a true partnership approach.

7. Production Capacity and Scalability

When evaluating potential partners, consider your current and future production needs. Can the company handle high-volume orders? Do they have multiple molding machines for different part sizes and materials?

Leading plastic injection molders maintain flexible production lines that can scale quickly as your demand grows. They also optimize production schedules to meet deadlines without compromising quality.

Scalable capacity ensures that your business can grow without needing to switch suppliers — saving time, money, and operational stress.

8. Transparent Pricing and Timely Delivery

Another key factor when comparing injection molding companies near me is transparency in pricing and project timelines. Reliable manufacturers provide detailed quotes, explaining the cost of tooling, materials, and production.

Be cautious of companies offering prices that seem too good to be true — low-cost shortcuts often lead to poor mold quality or production defects.

Professional plastic injection molding companies focus on long-term value: consistent quality, reduced waste, and fast delivery. At Rapid Molding, we ensure clear communication and realistic deadlines for every project.

9. Customer Service and Long-Term Partnership

Your relationship with a molding company shouldn’t end after the first production run. Look for a supplier that values communication, offers after-sales support, and helps with mold maintenance or design modifications.

Top-rated plastic injection molders see themselves as partners in your success. They proactively suggest improvements that enhance product performance, reduce cycle times, or optimize costs.

When you work with a responsive, customer-focused manufacturer, you gain more than just parts — you gain a strategic partner dedicated to your brand’s growth.

Conclusion

Finding the right injection molding companies near me requires more than a simple online search. You need a partner with proven expertise, cutting-edge technology, and a commitment to quality and reliability.

At Rapid Molding, we combine decades of experience in plastic injection molding with precision engineering and exceptional customer care. Our team of skilled plastic injection molders ensures every project — from prototype to high-volume production — meets the highest industry standards.

When you choose the right injection molding company, you’re not just outsourcing manufacturing — you’re investing in durability, precision, and performance that elevate your products and your brand.